Complete meals for $7.50 that can be customised by its customers and are inspired by the great culinary traditions of the world. It will also feature vegan and gluten-free choices

© Spyce

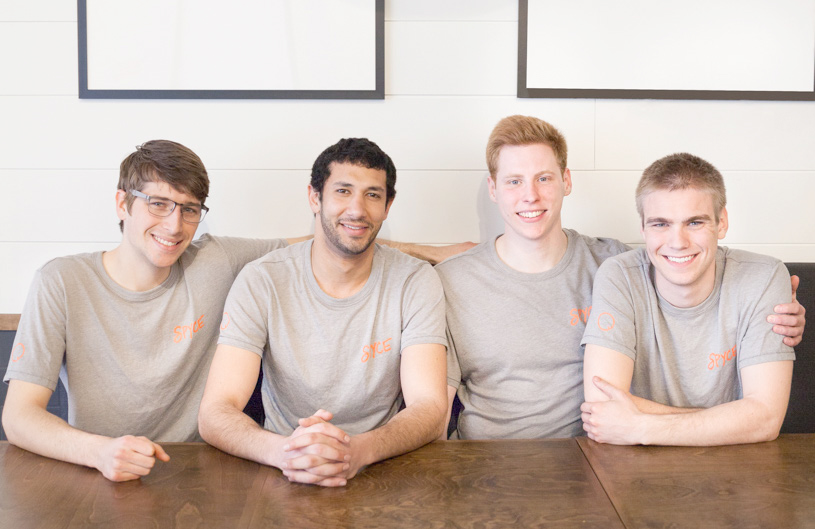

At 241 Washington Street in downtown Boston is Spyce, the first restaurant in the world with a robotic kitchen. Opened last May, the restaurant offers complete and varied meals, made entirely by robotsv, at the cost of a mere $7.50, while the staff is dedicated to refinishing the plates from an aesthetic point of view, and talking to the customers. This cutting-edge engineering work is the brainchild of four young researchers from the Massachusetts Institute of Technology (MIT) – Michael Farid, Kale Rogers, Luke Schlueter and Brady Knight – who developed the system in collaboration with Michelin-star chef Daniel Boulud, who then became the director of the kitchen and created all the recipes. «We came up with the concept of our restaurant in the hopes of solving a problem we all had to deal with. As students and athletes – commented the founders – we had a hard time finding a place to eat good healthy food at an affordable price. That is why we decided to combine good cuisine with technological innovation. The result of this process is Spyce, which blends science and hospitality into a single product, make delicious and nutritious meals affordable to everyone».

As the very name Spyce suggests, the recipes are distinguished in particular by their spices, by the aromas and consistencies of the international dishes.

Furthermore, each dish can be customised to meet customer tastes and requirements. There are vegetarian, gluten-free and vegan alternatives. There are in fact many different variations on the recipes, with Indian, Thai, Lebanese, Latin and Korean versions. The presentation of the plates, to which the same attention must be paid as to the flavour, is the work of the restaurant staff, the Gard Manager who gives them the final touch. The menus are prepared in “bowls”, with a balanced combination of ingredients such as vegetables, seeds, grains, seafood and chicken. One example is the recipe called “Roma” which includes roast chicken, pasta with tomato sauce and garlic, bruschette, ricotta whipped with lemon peel and breadcrumbs. There is also a selection with whole-grain rice that also includes roast chicken, sautéed cabbage, cucumber salad, blueberry sauce and white sauce.

But how does the robotic kitchen work? The operations are all executed by seven mechanical arms and seven woks, which are heated by induction, a precise and efficient method that saves energy compared to other methods.

© Spyce

Customers place their orders on a tablet and when the input is received, the requested ingredients are poured into the hoppers from the refrigerated cell, divided into portions and combined in the automatic works, which complete the cooking process before the mechanical arms ladle the food into the bowls, ready to be garnished and served. Waiting time? Three minutes. There is also great attention to sanitary concerns. The robotic kitchen, certified by the National Sanitation Foundation (NFS), cleans and sanitizes the woks after each meal it cooks. It is programmed to monitor the temperature, refrigeration, water and all the components of the refrigerator that come into contact with the food are regularly removed and washed by the staff.

© ALL RIGHTS RESERVED

translation by Olga Barmine